1 June 2022 – The integration of reference electrodes into Li-ion battery cell is envisioned as a potential tool to unlock novel sensing functionalities into current Battery Management Systems (BMS), providing accurate estimates for states of charge, health, power, energy and safety (SoX) cell indicators, along with other early-failure indicators.

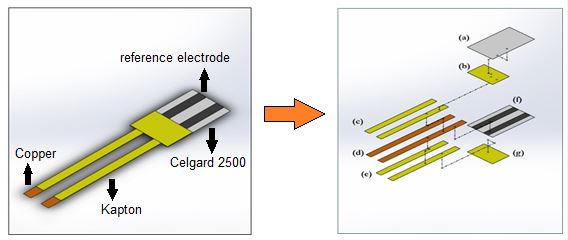

To take full advantage of the flat, non-bulky geometry of reference electrodes based on wet-jet milled graphene nanoflakes and printed on Celgard 2500 separators, flat-flex wiring must be developed to connect the reference electrode to the external circuitry and, thus, to the BMS.

The Li-ion battery pouch cell prototypes were assembled using a NMC 622 cathode, a graphite anode, a printed graphene-based reference electrode on Celgard 2500 separator, and LiPF6 EC:DEC (1:1) 1 M commercial electrolyte, connecting the electrodes by means of pressure-aided Cu tapes (partially isolated by Kapton insulators).

The designed flat-flex wiring for the electrical connection of the electrodes will be used to assemble Li-ion battery pouch cells integrating sensing reference electrodes. The latter will be used for in-situ EIS measurements, in-operando measurements of the electrolyte conductivity and electrodes’ potentials monitoring.

The developed cell configurations will improve the QRL and safety of the current Li-ion battery systems, enabling advanced multifunctional BMSs exploiting the information (e.g., SoX indicators) acquired with the graphene-based reference electrodes.

For the full report, click here.

Involved partners: BDM, POL