Project introduction

SENSIBAT’s overall objective is to develop a sensing technology for Li-ion batteries that measures in real-time the internal battery cell temperature, pressure (e.g. mechanical strain, gas evolution) conductivity and impedance (separately for the anode, cathode and electrolyte). The data and insights from these new sensing technologies will be used for the development of improved state estimator functions based on an improved understanding of how, where and when degradation and failure mechanisms occur. These functions will be included in the BMS.

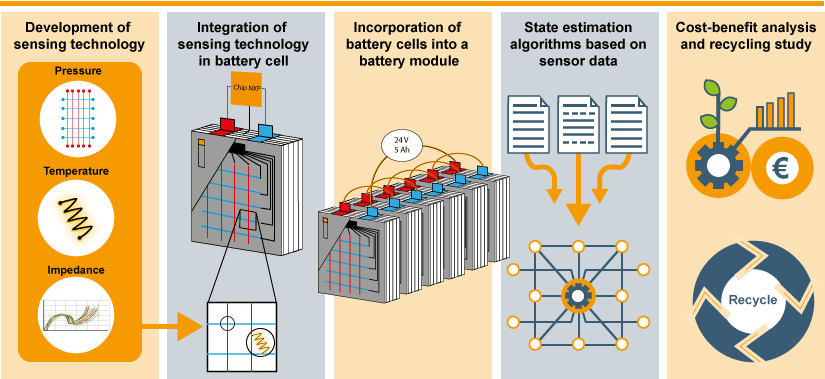

SENSIBAT’s approach consists of five steps:

1) develop the required battery cell sensor technology,

2) subsequently integrate this sensor technology into 1Ah and 5Ah pouch battery cells

3) incorporate the 5 Ah cells in a 24V battery module with BMS,

4) use the data from the internal sensing technologies to develop robust and advanced state estimation functions. Several state (SOC/SOH/SOE/SOP) estimation algorithms will be improved, better forecasting algorithms and novel safety concepts (SOS) will be created,

5) carry out a cost-benefit analysis for the batteries with sensors as well as a recycling study of the cells.

Improved understanding about the nature and timing of unwanted internal battery processes enables faster and more accurate control of the individual cells in a battery system during operation.

More accurate control stretches the possibilities of fast charging and discharging, increases the usable battery capacity and therefore range in different weather conditions and gives a detailed usage history. It allows for better battery state forecasting, resulting in a longer lifetime and more economical use during its 1st and 2nd life. Sophisticated lifetime prediction models enable improved (preventive) maintenance schemes. SENSIBAT’s technology that will be developed for all Li NMC battery types, and can be transferred to serve other battery chemistry types.